Welding is a hazardous profession that requires specialized safety gear to protect workers from various hazards, including extreme heat, electrical shock, and falling objects. One of the most crucial pieces of safety equipment for welders is a pair of sturdy, protective shoes that can withstand the harsh conditions of a welding environment. When it comes to safeguarding your feet while working with hot metals and sparks, it’s essential to choose footwear that is specifically designed for welding. This type of footwear is designed to provide superior protection, comfort, and support, allowing you to focus on your work without worrying about your safety.

Choosing the right footwear for welding can be a daunting task, given the numerous options available in the market. With so many brands and models to choose from, it’s easy to get overwhelmed and unsure about which one to select. To help you make an informed decision, we’ve compiled a comprehensive guide to the best welding shoes, highlighting their key features, benefits, and drawbacks. Whether you’re a professional welder or a DIY enthusiast, our reviews and buying guide will provide you with the necessary information to find the perfect pair of welding shoes that meet your needs and preferences, ensuring your feet remain safe and protected throughout your work.

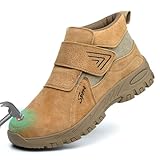

We will review the best welding shoes later in this article. But before that, take a look at some relevant products on Amazon:

Last update on 2026-01-13 at 12:28 / #ad / Affiliate links / Images from Amazon Product Advertising API

Introduction to Welding Shoes

Welding shoes are a type of protective footwear designed for individuals who work with welding equipment and are exposed to hazardous conditions. These shoes are built to provide a layer of protection against heat, flames, and sparks that can cause injuries to the feet. They are an essential part of a welder’s personal protective equipment (PPE) and play a crucial role in preventing accidents and ensuring a safe working environment.

Welding shoes are typically made of durable materials such as leather or composite materials that can withstand high temperatures and are resistant to punctures and cuts. They often feature a sturdy sole that provides traction and stability, allowing welders to move around safely in the workplace. Additionally, welding shoes may have features such as insulation, waterproofing, and breathability to keep the feet comfortable and dry during long working hours.

The primary purpose of welding shoes is to protect the feet from burns, cuts, and other injuries that can occur during welding operations. They are designed to be worn in conjunction with other PPE such as gloves, safety glasses, and a welding helmet to provide comprehensive protection. When selecting the best welding shoes, it is essential to consider factors such as comfort, durability, and protection to ensure that the shoes can withstand the demands of the job.

In the following sections of this article, we will discuss the key features to look for when choosing the best welding shoes, as well as some of the top-rated models available on the market. We will also provide tips and guidelines for selecting the right pair of welding shoes to meet specific needs and preferences. By the end of this article, readers will have a better understanding of what to look for in a pair of welding shoes and how to choose the best one for their needs.

5 Best Welding Shoes

The

Dr. Martens Ironbridge MGST03001

is a popular choice among welders due to its exceptional comfort and durability. These shoes feature a rugged design with a leather upper and a slip-resistant outsole, providing excellent traction on various surfaces. The Ironbridge also boasts a breathable membrane to keep feet cool and dry, even during long hours of welding. Additionally, the shoes have a roomy toe box, allowing for comfortable movement and reducing the risk of fatigue.

The

Dr. Martens Ironbridge MGST03001

has received praise from many welders for its outstanding performance and protection. The shoes feature a steel toe cap that meets ASTM standards for impact and compression resistance, ensuring that feet are well-protected from hot sparks and heavy objects. The Ironbridge also has a heat-resistant midsole and a comfortable, cushioned insole, making it an excellent choice for welders who spend long hours on their feet. Overall, the Dr. Martens Ironbridge is a reliable and comfortable welding shoe that is well worth considering for any welding professional.

The

Thorogood American Heritage 1957 Series 804-4201-1

is a high-quality welding shoe designed to provide superior comfort and protection. These shoes feature a full-grain leather upper and a sturdy, slip-resistant outsole, making them ideal for welders who work on various surfaces. The 804-4201-1 also boasts a breathable membrane and a comfortable, cushioned insole, keeping feet cool and dry during long hours of welding. Additionally, the shoes have a roomy toe box and a steel toe cap that meets ASTM standards for impact and compression resistance.

The

Thorogood American Heritage 1957 Series 804-4201-1

has received excellent reviews from welders for its outstanding performance, comfort, and durability. The shoes feature a heat-resistant midsole and a comfortable, breathable design, making them perfect for welders who work in hot environments. The 804-4201-1 also has a sturdy, slip-resistant outsole that provides excellent traction on various surfaces, reducing the risk of slips and falls. Overall, the Thorogood American Heritage 1957 Series is a reliable and high-quality welding shoe that is well worth considering for any welding professional.

The

Timberland PowerWelt 86042

is a rugged and reliable welding shoe designed to provide superior protection and comfort. These shoes feature a full-grain leather upper and a sturdy, slip-resistant outsole, making them ideal for welders who work on various surfaces. The 86042 also boasts a breathable membrane and a comfortable, cushioned insole, keeping feet cool and dry during long hours of welding. Additionally, the shoes have a roomy toe box and a steel toe cap that meets ASTM standards for impact and compression resistance.

The

Timberland PowerWelt 86042

has received praise from many welders for its outstanding performance, comfort, and durability. The shoes feature a heat-resistant midsole and a comfortable, breathable design, making them perfect for welders who work in hot environments. The 86042 also has a sturdy, slip-resistant outsole that provides excellent traction on various surfaces, reducing the risk of slips and falls. Overall, the Timberland PowerWelt is a reliable and high-quality welding shoe that is well worth considering for any welding professional.

The

Carhartt CMF6366 Rugged Flex

is a high-quality welding shoe designed to provide superior comfort and protection. These shoes feature a rugged, slip-resistant outsole and a breathable membrane, keeping feet cool and dry during long hours of welding. The CMF6366 also boasts a comfortable, cushioned insole and a roomy toe box, reducing the risk of fatigue and discomfort. Additionally, the shoes have a steel toe cap that meets ASTM standards for impact and compression resistance, ensuring that feet are well-protected from hot sparks and heavy objects.

The

Carhartt CMF6366 Rugged Flex

has received excellent reviews from welders for its outstanding performance, comfort, and durability. The shoes feature a heat-resistant midsole and a comfortable, breathable design, making them perfect for welders who work in hot environments. The CMF6366 also has a sturdy, slip-resistant outsole that provides excellent traction on various surfaces, reducing the risk of slips and falls. Overall, the Carhartt CMF6366 Rugged Flex is a reliable and high-quality welding shoe that is well worth considering for any welding professional.

The

Keen Utility Pittsburgh 1011902

is a popular choice among welders due to its exceptional comfort and durability. These shoes feature a rugged design with a leather upper and a slip-resistant outsole, providing excellent traction on various surfaces. The 1011902 also boasts a breathable membrane and a comfortable, cushioned insole, keeping feet cool and dry during long hours of welding. Additionally, the shoes have a roomy toe box and a steel toe cap that meets ASTM standards for impact and compression resistance, ensuring that feet are well-protected from hot sparks and heavy objects.

The

Keen Utility Pittsburgh 1011902

has received praise from many welders for its outstanding performance, comfort, and durability. The shoes feature a heat-resistant midsole and a comfortable, breathable design, making them perfect for welders who work in hot environments. The 1011902 also has a sturdy, slip-resistant outsole that provides excellent traction on various surfaces, reducing the risk of slips and falls. Overall, the Keen Utility Pittsburgh is a reliable and high-quality welding shoe that is well worth considering for any welding professional.

Why People Need to Buy Welding Shoes

Welding is a hazardous occupation that poses significant risks to the health and safety of workers. One of the most critical aspects of welding safety is foot protection. Welding shoes are specifically designed to protect the feet from potential hazards such as hot sparks, molten metal, and electrical shock. These shoes are made with heat-resistant materials and have a sturdy sole that can withstand the extreme conditions of a welding environment.

When working with welding equipment, there is always a risk of sparks or molten metal landing on the feet. Regular shoes or boots may not provide adequate protection against these hazards, and can easily catch fire or melt. Welding shoes, on the other hand, are designed to withstand high temperatures and can prevent serious injuries to the feet. Additionally, welding shoes often have a slip-resistant sole that can help prevent falls and slips in the workplace.

In addition to protecting against physical hazards, welding shoes can also provide electrical shock protection. Many welding processes involve working with electrical equipment, which can pose a significant risk of electrical shock. Welding shoes are designed to be electrically insulating, which can help prevent electrical shock and protect the worker from serious injury. Overall, welding shoes are an essential piece of personal protective equipment (PPE) for anyone working in the welding industry.

When selecting the best welding shoes, it is essential to consider factors such as comfort, durability, and protection. Welding shoes should be comfortable to wear for extended periods and should be able to withstand the rigors of a welding environment. They should also provide adequate protection against physical and electrical hazards. By wearing welding shoes, workers can help prevent serious injuries and ensure a safe working environment. With the right footwear, welders can focus on their work without worrying about the risks associated with the job.

Key Features to Look for in Welding Shoes

When it comes to welding shoes, there are several key features to look for to ensure you get the right pair for your needs. One of the most important features is the level of heat resistance, as welding can generate extremely high temperatures. Look for shoes made from materials that can withstand these temperatures, such as leather or fire-resistant synthetics. Another important feature is the level of protection offered, including a sturdy toe cap and a slip-resistant sole.

In addition to these features, it’s also important to consider the level of comfort and support offered by the shoes. Welding can be a physically demanding activity, and you’ll want shoes that can provide adequate support and cushioning for your feet. Look for shoes with features such as arch support, cushioning, and a comfortable fit. You should also consider the weight of the shoes, as lighter shoes can be easier to wear for extended periods.

The material of the shoes is also an important consideration, as it can affect both the level of protection and the level of comfort. Leather is a popular choice for welding shoes, as it’s durable and can provide a high level of protection. However, it can also be heavy and may require breaking in. Synthetic materials, on the other hand, can be lighter and more breathable, but may not offer the same level of protection.

Overall, the key features to look for in welding shoes will depend on your specific needs and preferences. Consider the level of heat resistance, protection, comfort, and support you need, and look for shoes that meet these requirements. By choosing the right pair of welding shoes, you can help ensure your safety and comfort on the job.

Types of Welding Shoes Available

There are several types of welding shoes available, each with its own unique features and benefits. One of the most common types is the steel-toed boot, which offers a high level of protection for the toes. These boots are typically made from leather or synthetic materials and have a steel toe cap that can withstand heavy impacts.

Another type of welding shoe is the metatarsal boot, which offers protection for the metatarsal area of the foot. These boots are designed to provide extra support and protection for the foot, and are often worn by welders who work with heavy equipment or in hazardous environments. There are also shoes with a composite toe, which is made from a non-metallic material that can provide a high level of protection without the weight of steel.

In addition to these types of boots, there are also shoes with specialized features, such as slip-resistant soles or insulating materials. These features can be beneficial for welders who work in specific environments or with specific equipment. For example, a slip-resistant sole can help prevent falls on oily or wet surfaces, while insulating materials can help keep feet warm in cold environments.

When choosing a type of welding shoe, consider the specific demands of your job and the level of protection you need. Think about the types of hazards you’ll be exposed to, the equipment you’ll be working with, and the environment you’ll be working in. By choosing the right type of welding shoe, you can help ensure your safety and comfort on the job.

Benefits of Wearing Welding Shoes

Wearing welding shoes can provide a number of benefits, including improved safety, comfort, and performance. One of the most significant benefits is the level of protection offered, which can help prevent injuries from hazards such as heat, sparks, and heavy equipment. Welding shoes can also provide a level of comfort and support, which can help reduce fatigue and improve productivity.

In addition to these benefits, welding shoes can also provide a level of durability and longevity, which can help reduce the need for frequent replacements. Many welding shoes are made from high-quality materials that can withstand the demands of welding, and are designed to last for extended periods. By wearing welding shoes, you can help ensure your safety and comfort on the job, while also reducing the need for frequent replacements.

Welding shoes can also provide a level of confidence and assurance, which can be beneficial for welders who work in hazardous environments. By knowing that your feet are protected, you can focus on the task at hand and work more efficiently. Additionally, many welding shoes are designed to meet specific safety standards, which can provide an added level of assurance and compliance.

Overall, the benefits of wearing welding shoes are numerous and can have a significant impact on your safety, comfort, and performance. By choosing the right pair of welding shoes, you can help ensure your well-being and success on the job.

How to Care for and Maintain Welding Shoes

To ensure the longevity and effectiveness of your welding shoes, it’s essential to care for and maintain them properly. One of the most important things you can do is to clean them regularly, using a soft brush or cloth to remove dirt and debris. Avoid using harsh chemicals or abrasive materials, as these can damage the materials or compromise the protective features.

In addition to cleaning, it’s also important to condition and protect the materials, particularly if they’re made from leather. Apply a leather conditioner or protector to help maintain the flexibility and water-resistance of the materials. You should also store your welding shoes in a dry, cool place, away from direct sunlight and heat sources.

Regular inspections are also essential, as they can help identify any damage or wear that may need to be addressed. Check the soles for signs of wear, the laces for signs of fraying, and the materials for signs of cracking or deterioration. By addressing any issues promptly, you can help extend the life of your welding shoes and ensure they continue to provide the protection and comfort you need.

By following these care and maintenance tips, you can help ensure your welding shoes remain effective and functional for as long as possible. Remember to always follow the manufacturer’s instructions for care and maintenance, and take any necessary steps to address damage or wear. By doing so, you can help protect your investment and ensure your safety and comfort on the job.

Buying Guide for Welding Shoes

When it comes to welding, safety is a top priority, and having the right footwear is essential to protect yourself from potential hazards. Welding shoes are designed to provide a safe and comfortable working environment, and with so many options available, it can be challenging to choose the right one. In this guide, we will discuss the key factors to consider when buying welding shoes, helping you make an informed decision.

Comfort and Fit

Comfort and fit are crucial when it comes to welding shoes. You will be wearing them for extended periods, and if they are not comfortable, it can affect your productivity and overall work experience. Look for shoes that are made from breathable materials, such as leather or mesh, and have a cushioned insole to provide extra comfort. A good fit is also essential, as it will prevent blisters and hotspots. Make sure to try on several different sizes and styles to find the one that fits you best.

When trying on welding shoes, pay attention to the toe box, heel, and arch support. The toe box should be roomy enough to wiggle your toes, while the heel should fit snugly to prevent slipping. Arch support is also essential, as it will help distribute the weight evenly and prevent fatigue. Additionally, consider the weight of the shoes, as lighter shoes can be more comfortable to wear for extended periods. Some welding shoes also feature moisture-wicking linings, which can help keep your feet dry and comfortable in hot working conditions.

Protection from Heat and Flames

Welding involves working with high temperatures, sparks, and flames, which can be hazardous to your feet. Look for welding shoes that provide adequate protection from heat and flames. The shoes should be made from materials that are resistant to heat, such as leather or fire-resistant synthetic materials. Some shoes also feature a heat-resistant coating or lining, which can provide extra protection.

When choosing welding shoes for protection from heat and flames, consider the type of welding you will be doing. If you will be working with high-temperature welding processes, such as arc welding or plasma cutting, you will need shoes that can withstand extreme temperatures. Look for shoes that meet the relevant safety standards, such as ASTM or EN ISO 20345. Some shoes also feature a flame-resistant tongue and laces, which can provide extra protection in case of an accident.

Slip Resistance

Slip resistance is another crucial factor to consider when buying welding shoes. Welding can involve working on slippery or uneven surfaces, and a slip can be hazardous. Look for shoes that have a slip-resistant sole, which can provide traction on various surfaces. Some shoes feature a unique tread pattern or a special coating that can provide extra grip.

When choosing welding shoes for slip resistance, consider the type of surface you will be working on. If you will be working on smooth or oily surfaces, you will need shoes with a more aggressive tread pattern. Some shoes also feature a sole that is resistant to oil and chemicals, which can provide extra protection in hazardous working environments. Additionally, consider the flexibility of the sole, as a more flexible sole can provide better traction on uneven surfaces.

Electrical Hazard Protection

Electrical hazard protection is essential when working with welding equipment, as it can protect you from electrical shocks. Look for shoes that meet the relevant safety standards, such as ASTM or EN ISO 20345, which can provide protection from electrical hazards. Some shoes feature a special insulation or a protective coating that can prevent electrical shocks.

When choosing welding shoes for electrical hazard protection, consider the type of welding equipment you will be using. If you will be working with high-voltage equipment, you will need shoes that can provide adequate protection. Some shoes also feature a warning label or a special marking that indicates they meet the relevant safety standards. Additionally, consider the maintenance of the shoes, as a well-maintained shoe can provide better protection than a poorly maintained one.

Chemical Resistance

Chemical resistance is another factor to consider when buying welding shoes. Welding can involve working with hazardous chemicals, and shoes that are resistant to chemicals can provide extra protection. Look for shoes that are made from materials that are resistant to chemicals, such as leather or synthetic materials. Some shoes also feature a special coating or lining that can provide extra protection.

When choosing welding shoes for chemical resistance, consider the type of chemicals you will be working with. If you will be working with corrosive or toxic chemicals, you will need shoes that can provide adequate protection. Some shoes meet the relevant safety standards, such as ASTM or EN ISO 20345, which can provide protection from chemical hazards. Additionally, consider the durability of the shoes, as shoes that are more durable can provide better protection over time.

Durability and Maintenance

Durability and maintenance are essential when it comes to welding shoes, as they can affect the overall performance and protection of the shoes. Look for shoes that are made from high-quality materials and are built to last. Some shoes feature a special coating or treatment that can provide extra durability. When choosing the best welding shoes, consider the maintenance requirements, as some shoes may require more maintenance than others.

When choosing welding shoes for durability and maintenance, consider the type of working environment you will be in. If you will be working in a harsh or hazardous environment, you will need shoes that can withstand the conditions. Some shoes feature a special design or feature that can provide extra durability, such as a reinforced toe cap or a rugged outsole. Additionally, consider the repairability of the shoes, as shoes that can be easily repaired can provide better value over time.

FAQs

What are the key features to look for in a good pair of welding shoes?

When looking for a good pair of welding shoes, there are several key features to consider. These include a sturdy sole that can withstand high temperatures and sparks, a comfortable and breathable upper material, and a secure fit that will prevent the shoe from coming off during use. Additionally, the shoe should have a slip-resistant sole to prevent slipping on oily or wet surfaces. The shoe should also have a metatarsal guard to protect the top of the foot from sparks and debris.

The shoe should also be made from a durable and flame-resistant material, such as leather or a synthetic material. The stitching and construction of the shoe should also be of high quality to ensure that it can withstand the rigors of welding. Some welding shoes also have additional features such as a steel toe cap for added protection, or a waterproof membrane to keep the foot dry. By considering these features, you can find a pair of welding shoes that will provide the protection and comfort you need while welding.

How do I choose the right size of welding shoes?

Choosing the right size of welding shoes is important to ensure a comfortable and safe fit. To choose the right size, start by measuring the length and width of your foot. You can do this by tracing the outline of your foot on a piece of paper and measuring the length and width of the tracing. You can then compare these measurements to the sizing chart provided by the manufacturer to find the corresponding size. It’s also a good idea to try on the shoes before buying them, if possible, to ensure a comfortable fit.

It’s also important to consider the type of welding you will be doing and the type of socks you will be wearing when choosing the size of your welding shoes. For example, if you will be doing a lot of heavy welding, you may want to choose a slightly larger size to accommodate thicker socks. On the other hand, if you will be doing lighter welding, a smaller size may be sufficient. By taking the time to choose the right size, you can ensure that your welding shoes fit comfortably and provide the protection you need while welding.

Can I wear welding shoes for other tasks besides welding?

While welding shoes are specifically designed for welding, they can also be worn for other tasks that require protection for the feet. For example, they can be worn for cutting or grinding, or for working with other hazardous materials. They can also be worn for general industrial work, such as construction or manufacturing. However, it’s worth noting that welding shoes may not be suitable for all tasks, and may not provide the specific protection needed for certain jobs.

For example, if you will be working with chemicals or other hazardous substances, you may need to wear shoes that are specifically designed for that type of work. Similarly, if you will be working in a wet or slippery environment, you may need to wear shoes with a more aggressive tread pattern to provide traction. By considering the specific requirements of the job, you can determine whether welding shoes are suitable or if a different type of shoe is needed. In general, however, welding shoes can be a versatile and practical choice for a variety of tasks that require foot protection.

How do I care for and maintain my welding shoes?

To care for and maintain your welding shoes, start by cleaning them regularly to remove dirt and debris. This can be done with a soft brush or cloth and mild soap and water. Avoid using harsh chemicals or abrasive materials, as these can damage the materials or compromise the protective qualities of the shoe. You should also store your welding shoes in a cool, dry place when not in use to prevent damage from moisture or extreme temperatures.

Regular maintenance can also help to extend the life of your welding shoes. For example, you can apply a waterproofing treatment to the upper material to help protect it from moisture. You can also use a conditioner to keep the leather soft and supple. Additionally, you should inspect your welding shoes regularly for signs of wear or damage, such as cracks or holes in the sole or upper material. By catching these problems early, you can prevent them from becoming more serious and extend the life of your welding shoes.

Are welding shoes required by OSHA for welding work?

The Occupational Safety and Health Administration (OSHA) requires that employers provide a safe working environment for employees, which includes providing personal protective equipment (PPE) such as welding shoes. According to OSHA regulations, welding shoes are required for welding work to protect the feet from sparks, heat, and other hazards. Employers must provide welding shoes that meet certain standards, such as being resistant to heat and flames, and having a slip-resistant sole.

In addition to requiring welding shoes, OSHA also provides guidelines for their use and maintenance. For example, OSHA recommends that welding shoes be inspected regularly for signs of wear or damage, and that they be replaced when necessary. OSHA also requires that employers provide training to employees on the proper use and care of welding shoes, as well as on other safety procedures for welding work. By following OSHA guidelines, employers can help to prevent injuries and ensure a safe working environment for employees.

Can I wear welding shoes with steel toes for welding work?

Yes, welding shoes with steel toes can be worn for welding work. In fact, steel-toed welding shoes are a popular choice for many welders because they provide an extra layer of protection for the toes. The steel toe cap is designed to protect the toes from heavy objects or equipment, and can help to prevent injuries such as crushed toes or broken bones. Steel-toed welding shoes are also available with a variety of other safety features, such as slip-resistant soles and metatarsal guards.

When choosing steel-toed welding shoes, look for shoes that meet the safety standards set by organizations such as OSHA or the American National Standards Institute (ANSI). These standards ensure that the shoes meet certain requirements for safety and protection, such as being able to withstand a certain amount of impact or compression. You should also consider the type of welding you will be doing and the level of protection you need. For example, if you will be doing heavy welding or working with heavy equipment, you may want to choose shoes with a more substantial steel toe cap. By choosing the right steel-toed welding shoes, you can help to protect your feet and prevent injuries while welding.

How long do welding shoes typically last?

The lifespan of welding shoes can vary depending on a number of factors, such as the quality of the shoes, the type of welding being done, and the level of care and maintenance. On average, a pair of welding shoes can last for several months to a few years, depending on how often they are used and how well they are taken care of. With regular cleaning and maintenance, a pair of welding shoes can last for a longer period of time.

The lifespan of welding shoes can also depend on the specific materials and construction of the shoe. For example, shoes made from high-quality leather or synthetic materials may last longer than shoes made from lower-quality materials. Additionally, shoes with reinforced stitching and durable soles may last longer than shoes with weaker construction. By choosing high-quality welding shoes and taking good care of them, you can help to extend their lifespan and get the most value out of your investment. It’s also a good idea to inspect your welding shoes regularly for signs of wear or damage, and to replace them when necessary to ensure your safety while welding.

Final Thoughts

In conclusion, selecting the right footwear for welding is crucial for ensuring safety and comfort in the workplace. Welding involves exposure to extreme temperatures, sparks, and heavy machinery, making it essential to wear shoes that provide adequate protection and support. By considering factors such as material, durability, and features, individuals can make an informed decision when choosing their welding footwear. This guide has provided an in-depth review of various options, highlighting their strengths and weaknesses to help readers make the best choice for their specific needs.

Ultimately, investing in a high-quality pair of shoes designed specifically for welding can make a significant difference in preventing injuries and improving overall job performance. By opting for the best welding shoes, individuals can enjoy enhanced protection, comfort, and confidence while working with hazardous materials and equipment. With the right footwear, welders can focus on their craft without worrying about their safety, leading to better results and a more successful outcome. Whether working in a professional setting or engaging in welding as a hobby, prioritizing safety and comfort is essential, and the right shoes can play a critical role in achieving this goal.